Laminated glass is a type of safety glass that is composed of two or more layers of glass bonded together with a layer of polyvinyl butyral (PVB) or other interlayer materials. This interlayer holds the glass layers together in the event of breakage, providing increased safety and security. Laminated glass also offers various customization options, including the addition of decorative interlayers for aesthetic appeal and improved energy efficiency.

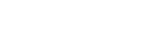

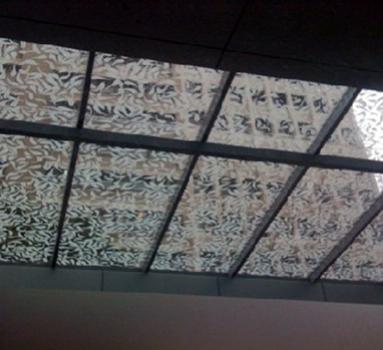

K&K Glass offers comprehensive customization options for your architectural glass needs, ensuring optimal energy efficiency, durability, and noise control. Our custom laminated glass can be tailored to your specific requirements, drawing from a vast selection of glass and interlayer materials, such as PVB. We also offer further customization options, including the addition of decorative coloured interlayers. For superior performance, safety, and noise reduction, our custom laminated glass can be combined with an Insulated Glass Unit.

Features:

- Consists of two or more layers of glass bonded together with an interlayer material

- Offers improved safety and security due to the interlayer holding the glass together upon breakage

- Can be customized with various interlayer materials for additional features like noise reduction, UV protection, and energy efficiency

- Resistant to penetration and forced entry

- Provides enhanced protection against natural disasters like hurricanes, tornadoes, and earthquakes

Benefits:

- Reduces the risk of injury from broken glass

- Provides increased safety and security for buildings and homes

- Reduces noise transmission for a quieter indoor environment

- Offers improved energy efficiency and cost savings

- Provides protection against UV radiation, which can cause fading of interior furnishings and artwork

- Adds an aesthetic appeal with customizable decorative interlayers

- Increases property value and marketability.